This is just a preview. Read the full case study by clicking the link below.

Overview

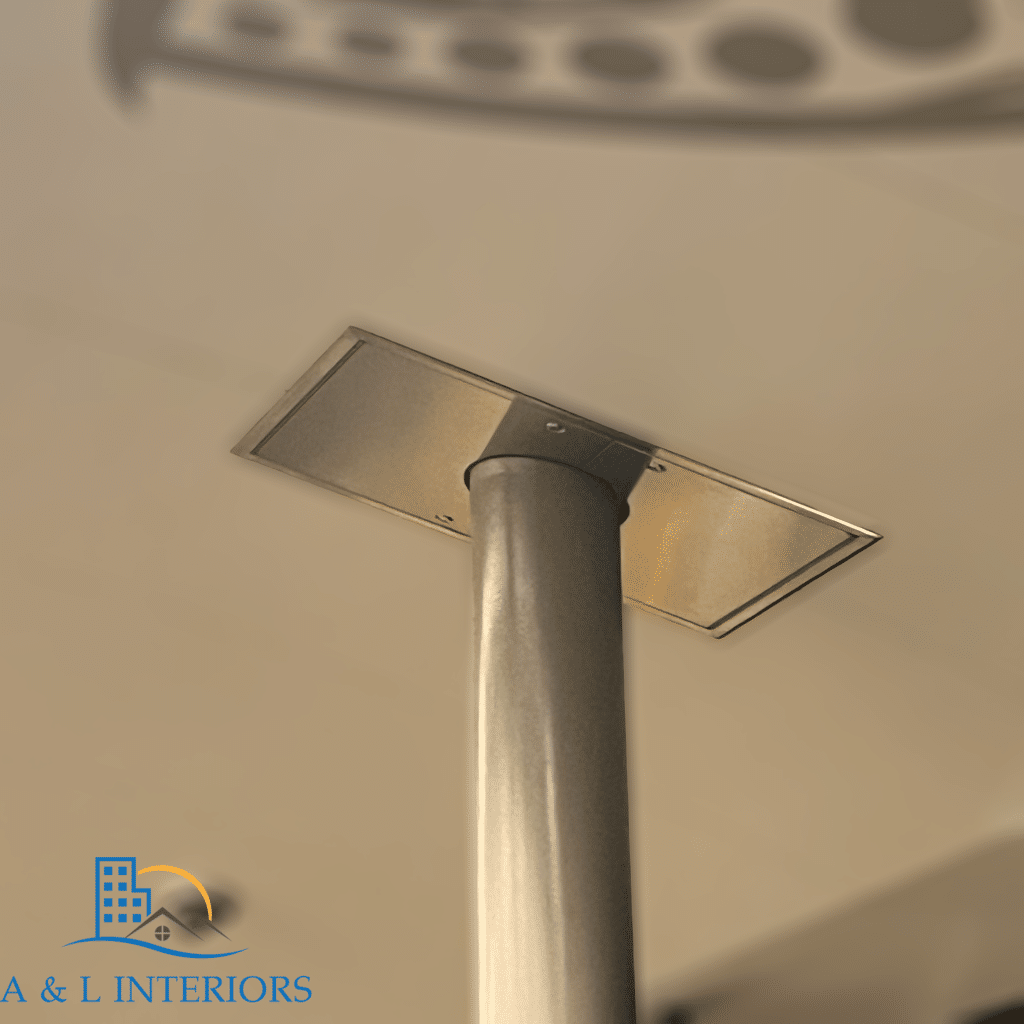

As part of the upgrades to the NSW ferry wharves, A&L Interiors partnered with Trafalgar Access to tackle a unique set of challenges. The project aimed not only to modernise the infrastructure but also to ensure its resilience against the demanding coastal environment, all while maintaining a sharp eye on aesthetic integrity and functionality.

The Challenge

As the project progressed, a critical and unforeseen challenge emerged that threatened the safety and integrity of the newly upgraded structures: the loosening of bolts within the ceiling structures due to the persistent high winds, characteristic of the wharves environment.

The corrosive impact of the salty sea air added another layer of complexity, threatening the longevity of metal components.

Moreover, integrating any new solution with the upgraded wharves aesthetic vision was paramount.

The Delivery

In response, Trafalgar Access introduced a meticulously designed solution: Custom Double Door 316-Grade Stainless Steel Panels. This material was selected for its superior corrosion resistance and strength, essential qualities in the harsh maritime environment of the NSW ferry wharves. Further, the panels’ design was conceived with aesthetic harmony in mind. Featuring bespoke hole cut-outs, they blended seamlessly into the ceiling architecture, appearing as integral components of the wharves design rather than functional add-ons.

This project prime example of how custom-engineered access panels can beautifully merge functionality with aesthetic appeal in public infrastructure. Addressing complex technical challenges, the project placed a premium on safety, durability, and an enhanced visual aesthetic.

This is just a preview. Read the full case study by clicking the link below.

-

Metal Access Panels

- Select options This product has multiple variants. The options may be chosen on the product page

-

FyreSHIELD™ Fire Rated Access Panels for Shafts

- Select options This product has multiple variants. The options may be chosen on the product page

-

Touch Latch Metal Access Panels

- Select options This product has multiple variants. The options may be chosen on the product page